Results have been encouraging with the new mordant I have working on. It etches the three common metals used by printmakers, with zinc dissolving the fast and copper the slowest. While there seems to a number of ways to mix a suitable mordant, I have decided to make a stock solution that will work best for copper, but too strong for the other metals - but diluting them to suit the image.

Again I have used toner washes to find out the limits of a mordant as the fine detail the particles can give really tests both the etch and metal. In all cases, I don’t apply blockout to the plate beyond the image as I want to see how well the ground has stood up against a mordant in the very thin layer, so bear with the breaks in the background. The toner copper plate was etched in a small vertical tank where the solution is gently recirculate by air bubbles. The remaining plates were etched in trays.

Again I have used toner washes to find out the limits of a mordant as the fine detail the particles can give really tests both the etch and metal. In all cases, I don’t apply blockout to the plate beyond the image as I want to see how well the ground has stood up against a mordant in the very thin layer, so bear with the breaks in the background. The toner copper plate was etched in a small vertical tank where the solution is gently recirculate by air bubbles. The remaining plates were etched in trays.

These plates are not made as works of art but for important information about depth of etch and quality of edges etc. The copper plate is a piece of scrap I was able to acquire, but it has seen days at one time. I didn’t need to take the time to polish the surface for these tests.

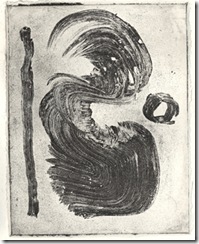

Zinc etches the fastest producing very fine bubbles that keep the lines clean, but not big enough to block the etching action – no need for feathers. This plate printed thin toner brush lines, just like in lithography, but without the very fine detail of waterless lithography images. The ink was Daniel Smith Standard Black that was modified with their DS relief ink, or with a water soluble ink I ground myself. This makes wiping easier but produces more background tone.

Zinc etches the fastest producing very fine bubbles that keep the lines clean, but not big enough to block the etching action – no need for feathers. This plate printed thin toner brush lines, just like in lithography, but without the very fine detail of waterless lithography images. The ink was Daniel Smith Standard Black that was modified with their DS relief ink, or with a water soluble ink I ground myself. This makes wiping easier but produces more background tone.

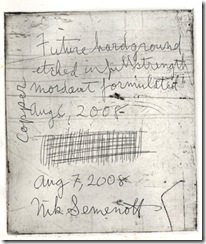

This copper plate was etched in a tray, using Future floor polish as a hardground. This copper plate also came from the same scrap heap and contains deep scratches that don’t take away from the information I hoped to get. In the tray this plate took over 1/2 hour to etch, but it still not as deep as I would like. The image has been flipped horizontally to make it easier to read the text.

This copper plate was etched in a tray, using Future floor polish as a hardground. This copper plate also came from the same scrap heap and contains deep scratches that don’t take away from the information I hoped to get. In the tray this plate took over 1/2 hour to etch, but it still not as deep as I would like. The image has been flipped horizontally to make it easier to read the text.

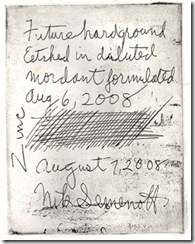

This zinc plate also had a Future hardground, which was not applied carefully, but etched in a diluted version (75% water) of the stock solution used on the copper plate. Etching took only about 7 minutes and I believe I would dilute the mordant by even more next time. The used mordant was regenerated quickly or could have been kept to do it by itself over a couple of hours.

This zinc plate also had a Future hardground, which was not applied carefully, but etched in a diluted version (75% water) of the stock solution used on the copper plate. Etching took only about 7 minutes and I believe I would dilute the mordant by even more next time. The used mordant was regenerated quickly or could have been kept to do it by itself over a couple of hours.

When I finish all my research and get some feedback from a few dedicated etchers who have agreed to test the mordant, I plan to publish in the international refereed journal LEONARDO; as I have with all my other innovations. Hopefully, once the manuscript is sent to the publisher, I will reveal the formula and method of working.