|

|

It is written from a personal point of view on how he developed the processes now taking hold internationally in the printmaking community. There is much information on how to make your studio or classroom safer by using these new methods of making prints. By Nik Semenoff D. Litt |

|

|

An exciting new way of publishing, using DVD technology to surf the pages on your computer. This disc covers how to use the new processes developed by Nik Semenoff over his many years as artist and printmaker. Using the marvels of the computer age, it allows the reader to quickly move to important related information with a simple click of the mouse and a new link. By means of PDF files; text, photographs, graphics, and videos are available. Using free Adobe Reader #9, you can retrieve the data quickly and easily, then print out what you want for easy reference in your studio Toner Images in all media

|

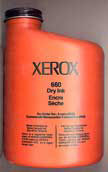

It is much easier to produce images by using the dry copier toner technique he developed in 1985. Toner used in both traditional and his waterless lithographic method can be processed faster and easier with less surprises for the artist and printer. Used in lithography, intaglio and screen printing, this unusual material can be applied directly to plates or used for lithographic photo plates, photo intaglio, photopolymer plates and screen exposures because its’ opaqueness. |

|

|

Toner on aluminium plate - printed by traditional litho |

Toner on Mylar exposed for screen printing |

Todays' toners contain black iron oxide, which should put to rest those who are concerned about the toxicity of carbon black pigments. All toners are microencapsulated in plastics to make them heat sentive for bonding to paper and easier for cleanup in case of spills. They are remarkable materials that can be formed into chalks for charcoal like drawings or applied in washes ranging from delicate fine tints to robust dramatic expression. |

.

|

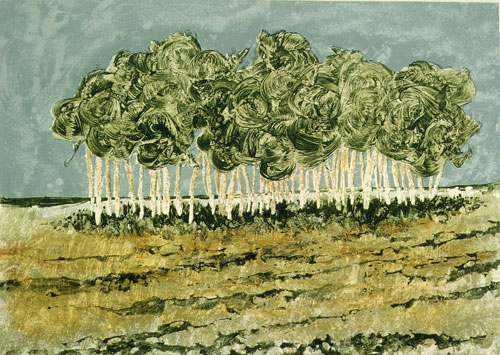

Waterless lithography By using his waterless lithographic process, brighter colors and better registration are the results on the paper. This revolutionary development has made lithography simpler, allowing students and artists to use various techniques to express their creativity much easier. Toner can be used directly on plates with both traditional and the new waterless process that is becoming popular amongst printmakers. Also great for photo plates and images on Mylar . |

|

|

Copper Sulfate Mordant Intaglio image are now safer to produce using the electro-chemical action of copper salts on zinc and aluminium. No long is dangerous nitric acid need in the studio. Toner can be used in electro-etching, photo plates, the new polymer plastic plates and directly on plates as a negative or positive image. With addition of oxygen, the mordant will etch copper plates and can be replenished very easily many times with hydrogen peroxide. |

Waterbased Screen Ink using Safe Starch Materials Screen prints using simple starch based ink and pigments produce finer detail on paper, as well as being safer and cheaper to use. This simple to use waterbased ink makes the studio much safer, while not being as expensive to use as any of the commercial screen printing inks. This image was made with toner washes on Mylar, which was exposed to screen emulsion using only one coat. |

|

Waterless Lithography |

|

Waterless lithography, the most exciting new technoloy that makes it much easier to produce colorful edition with no surprises. Using readily available common material locally, a durable ink rejection layer is applied to the plate that can produce the most delicate tints possible using any of the lithography process. Use of a subplate lets you roll off the plate, which makes it more pleasant to cleanup after the edition is finished. Reverses are possible just as in traditional lithography, but deciding ahead of time that it was required in the edition. The 3-part roller makes it easier to print waterless as well as traditional litho. |

|

Although toner combined with waterless lithography allows for simple creation of editions, they can also be used for photopositive techniques for greater freedom of expression. Todays use of computer assisted images allows the artist to produce much more complicated prints than the above example, which was done by toner transfers from Mylar and newsprint unto many-time recycled backs of used plates. All of this is explained in simple terms with use of photographs, graphics and video clips. Using the full limits of PDF files and the new technologies, information can be quickly acquired through the computer monitor, or output on your printer. Everything is explained with a personal touch by the printmaker who is responsible for changing how prints may be produced in the future. |

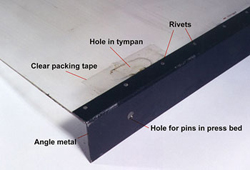

Construction of Equipment and Useful Materials |

|

|

|

A section on making equipment needed in the new safer studios demanded by todays’ printmakers. There are many items that will make printing editions much easier by using the information within this section. Information on chemicals for safer printing in the studio, including a number of suggestions for solvent free cleanup. |

These are the sections covered in the DVD:

|

What People Say: New Directions in Printmaking: The Technical Side Grapheion's Links by Robert Horvitz |

|

|

|

|

How toner can be used in all media |

Using common caulking silicone to make waterless lithographic plates |

Instructions for making useful equipment to make printing easier |

| Examples of how the links work for random access of text and photographs that make it easy to understand and use the processes. Just click on any picture and you will access a PDF file for use on Adobe Reader. Because of the big PDF video files (23.5 & 16.3 MB) I have not included them within the downloads. |

Price for the DVD is $49.99 in Canadian funds, plus $9.00 for shipping. To Order your copy of the DVD, contact: e-mail contact: nik.semenoff@usask.ca |