|

|

In 1962, when I became engaged to my wife, I bought the customary diamond ring for her. As we prepared for the wedding, she purchased a tiara made of fake pearls and sparkly stones. The price was outragous and I talked her into return the piece as I was instead prepared to make her one out of sterling silver. My experience with gold and silversmithing was basically non-existent, but I had a nice workshop and was handy with tools. I was able to purchase some silver wire and solder, then proceeded to make a cornet. Moonstones and cultured pearls were included with the piece ending up much better than anyone expected. |

|

|

|

| Sterling silver tarnishes over time and this piece has not been used since May of 1962. We had hoped our children would wear it, but they chose for me to make them their own tiaras more to their liking. This tiara is kept in a wooden box that I built, which I covered with fine thin leather, then constructed a simple clasp and a lock based on ancient oriental design. |

|

This inspired me to try making our wedding rings, so I started to collect old gold jewelry for the metal. Books on goldsmithing were available and with them, I started my journey into this craft. Not satisfied with a simple band, I used three colors of gold, which I managed to alloy myself and solder together the pieces. This was not too difficult I thought and proceeded to take it up as a hobby to provide my new bride with better quality baubles etc. After about a year I attended a one week workshop by a European trained goldsmith and learned some useful hints. As I gathered tools and equipment, my skill grew and I considered I could better make a living as a goldsmith rather than stay as art director of the local TV station. |

|

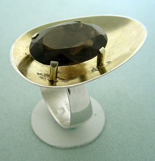

| Simple SS ring made for sale | Blue stone in bezel at end of ball | |

|

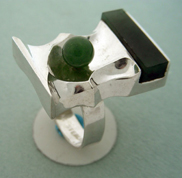

In the 60’s there was much Scandinavian influence on all design, including jewelry, and I was certainly affected by the simple lines. Besides the clean smooth surfaces were easier to work with and much of my early pieces kept to this principal. |  |

Sterling and ebony with embedded silver wire |

Sterling ring with jade stone |

|

|

|

|

| Formed sterling ring with synthetic stone | Double shelled with fused gold inside inner shell. Cultured pearl on a peg |

Topaz stone against fused gold on sterling silver |

|

In 1963 I left the television station to start freelancing in building architectural and historic models, along with commercial photography. I was soon starting to sell my silver and gold jewelry through a few outlets in Canada and even was selected to represent Canadian crafts for a traveling show throughout Europe, sponsored by the National Gallery. I began getting private commissions for both gold and silver pieces from local collectors, but the other parts of my freelance activities took too much of my time to expand much into goldsmithing. |

|

| Formed sterling with quartz material | Fabricated ring from sheet silver, wire |

|

|

Then on the advice of my accountant, I stopped selling jewelry because of the possibility the federal government adding the large luxury tax on jewelry unto the taxes of my other freelance activities. By 1965 a recession took over Canadians and freelancing started to look like a bad career choice, so I took a position as media specialist with the Extension Division at the University of Saskatchewan. |  |

Cast sterling ring with jade ball and slab |

Sterling fabricated ring using cast element within circle |

|

|

|

Ring fabricated from silver balls and wire that is soldered to a band |

Sterling ring with hollow ball to which gold particles were fused, then oxidized |

Ring fabricated from silver wire and balls soldered to a band |

Free form designs

|

|

Much of my early jewelry was constructed by silver soldering formed pieces of silver together as this is a basic method of production. I could make wire by pulling it through draw plates and thin down plates of silver in a rolling mill. When I discovered how molten silver poured into swirling water could form interesting organic shapes, I started to include them in rings and pendants. I made up my own gold plating solution and coated areas with 24 K gold to bring out variation of surface coloring. |

|

Double terminated quartz crystals |

|

Double terminated quartz is very unusual and interesting material to work with. It forms in a clay matrix and has facets on all sides, unlike quartz that is formed within geodes. Fractures and impurities only add to the interest of the crystals. So what is the best design for rings using these “Yonkers Diamonds”? I chose to keep angular shapes for these two rings to make them more like miniature sculptures. The ring on the left stands up on its’ own but can fit on a finger just as well. |

|

|

|

|

| Lost Wax Casting Using Other Materials besides Wax |

|

|

|

|

In time I decided to learn how to do lost wax casting and built my own centrifugal casting unit. A small potters kiln with an electronic control system I designed and built allowed me to burn out the investment for casting in both gold and silver. While I had enjoyed the clean simple lines of Scandinavian jewelry, I loved textures and more organic shapes, so this technique fitted me better in the long run. I found folded plastics, synthetic threads and styrofoam could all be used as well as the classical wax used by traditional goldsmiths. |

|

|

Dense Styrofoam was carved to shape and cast by lost wax technique. A cultured pearl hidden in recess. |

Centrifical casting using various cords, threads and styrofoam as originals |

|

Lost wax casting allows for shapes that are impossible by any other means. Ones imagination can run wild and sometimes it did in my case. |

|

Nice star |

Synthetic star sapphire in lost wax sterling silver |

|

|

|

Tourmaline natural crystals in matrix mounted in a lost wax cast silver ring. I could see it being worn by some ancient magician such as Merlin. |

Sterling ring using lost wax process. Chemically colored on surface. Stone is a banded agate on a peg. |

Wax put on top of a Styrofoan core, which was removed with acetone before investing. |

|

|

|

|

10K gold centrifical cast from cord matrix |

Aquamarine stone in sterling silver |

Another 10K gold cast ring |

|

|

|

This diamond ring contains more gold (19.7 grams) than the average rings purchased at a jewelers. The model was made from wax for casting by centrifical means. |

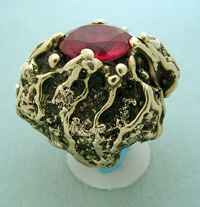

Synthetic ruby in centrifical cast 10 K gold |

Cast sterling ring with cultured pearl and chemical coloring |

|

|

|

The genuine amethyst ring is made by lost wax casting, using pink gold to match the stone color. |

Diamond set in white gold claws that was soldered unto the lost wax cast gold ring. Thread and wax was used to make the model |

Diamond ring I made for myself from 10K gold using styrofoam for model |

| Gold Soldered Rings |

|

A Few unusual rings I made. The diamond ring with blue lapis Lazuli and green Chrystophrase won a De Beers Consolidated major award for me at the Canadian Craft Council show in 1977. The gold portion is not solid by hollow, made up of sheet gold soldered at the edges. I cut and fit the stones as well. |

|

Like most women my wife loves diamonds, but I have been able to keep her happy because of my connection with the jewelry trade and ability to produce the many rings she has. I don’t like diamonds as well as other colored stones but to each her own. I loved making pendants, which may be a result of their popularity during the 60’s. Broaches are liked by older ladies so I have not made as many of them as other items. To photograph rings, it is customary to use some form of tent to prevent harsh shadows that obliterate detail, but takes away the sparkle of a diamond. |

|

|

|

One carot diamond in a cast gold ring |

Diamond rings worn by my wife

|

Diamond in soldered gold shapes |

|

|

|

|

The assembly of left over small diamonds was a project to fill a weekend. Made with 10K yellow gold and white gold prongs holding the diamonds. |

The gold wire frame ring contains an emerald as well as small lapis and chrysoprase. It actually is comfortable to wear if put on as I designed it to be worn |

10 K gold with Topaz in claws |

|

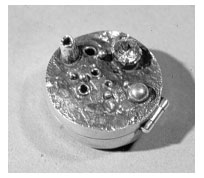

This interesting ring was made for a lady with severe arthritis in her hands. She could no longer wear her engagement ring as it would not fit over the finger. For this commission I produced a 14K gold ring with a gold spring loaded mechanism that fit at the palm side of her hand and held the ring firmly on her finger. Since she was not able to use her fingers normally, this did not impede the day to day use of her |

Rings made from Titanium

I have recently produced some titanium rings for weddings, using a small Unimat lathe. This does not require the close working eyesight I no long enjoy even with a jewelers loupe. |

|

|

|

|

| This ring was made using the surviving diamond earring my wife lost from the pair she constantly wore. The lapis is enclosed with gold and the titanium heated to produce blue color. | This ring is made by heating the metal until tough permanent oxides are formed, then the color was removed on the lathe | This ring was lathed to size, then a rough file used to add texture to the domed area. | The right ring is made of three parts, using silver between titanium and held together with silver rivets. This was very tricky as I had to use my rolling mill to thin down the hard titanium. Drilling titanium proved to be a challenge as small carbide bits broke too easy and high steel dulled too fast. |

Broaches

Broaches are not common today, but I can still see them worn by older ladies. Some of these are designed for heavier garments like coats as they are cast silver and would distort the thinner clothes. Most of these were commissions for which I had produced sketches for the client to pick the design they liked. |

|

|

|

|

| Sterling broach made by soldering formed pieces together. Stones are Persian turquoise obtained by client | Sterling silver lost wax casting, using thick acrylic paste to form the textures on the surface. A cubic zirconium is set in a sterling claw mount | Commissioned broach using beautiful lapis lazuli purchased from the best source, Afghanistan by a doctor who lived there for many years. Sheet silver construction. | Sterling circles with beaten edges and ball soldered together. The black opals were bought in Australia by the client to be made into something for his wife |

|

|

|

|

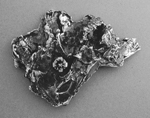

| Sterling silver lost wax method using pliable plastic and wax. The hanging form contains a cultured pearl | Sterling silver with granulated 10 K gold fused to sheet. Top form is cast metal pickled to leave fine silver on surface. Riveted to base sheet of metal | Broach with cultured pearl and gold and copper balls attached to sterling surface. | Sterling silver using sheared offcuts of sheet silver that were fused together by gentle heating of the surface - no solder used except to attach findings at back. |

|

|

|

|

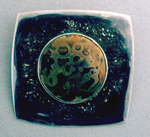

| Sterling silver sheet with fused gold applied by heating 10 K gold granules to melting point. The stone is a double terminated quartz crystal | Sterling metal with textured area around circular bezel containing a piece of Mokum metal, a popular metal working technique developed by the Japanese. Various colored metals are soldered together, then punched from the back and filed to reveal colors. | Sterling silver using my “anvilized” texture that was very popular. It consisted of beating the cut out sheet on an old badly abused anvil whose surface was heavily pitted. One cultured pearl and a couple silver balls added to surface. | Ebony held in bezel with silver inlay on a thick sterling sheet. |

Pendents

Pendents from the hippy days of the 60’s. Some used leather thongs to which I made and attached simple hook fasteners. Others demanded hand made chains, which are rather time consuming to produce. No color slides for these pieces as I used a 35 mm and a macro lens |

|

|

|

|

| Centrifical cast pendent from silver, using folded plastic as the model, then textures added with wax. | Mostly sterling silver except for bottom form, which is titanium. Top shape is chemically treated to bring out colors, then coated with plastic. | Commissioned piece using words given me by client and etched into silver using photo etching techniques. Stones are synthetic blue sapphires. | Cast sterling pendant using lost wax method. Texture built up on wax sheet. Hand made chain. |

|

|

|

|

| Lost wax casting process for silver pieces. A wax model was taken from silicone mold that was used in a pendant shown above. Copper ring and tube along the top, which also has brass tubes solder unto it. Red agate on peg. | Constructed sterling pendant with fused 10K gold on surface. Jade stone within center form. Commercial silver chain | Sterling sheet with “anvilized” texture and 24K gold plated form. Bottom form is cast silver with red agate. | Cultured pearls on sterling cast piece with added wire and tube. |

|

|

|

|

| Actually a pendant that can also be worn as a broach resembling a medal of sorts. The top portion is lost wax casting and the rest constructed from sheet silver. Cast shape was taken from an textured acrylic form using diluted silicone to produce wax models for burnout. The stone is a large cubic. | Lost wax casting with turquoise hanging ball, hand made chain. Surface was not polished and left with a layer of fine silver after pickling in acid. | Sterling sheets were “anvilized” and soldered together. Fused 10 K gold are the yellow areas under the cross pieces. Blue lapis lazuli mounted on peg | Sterling silver with 10K gold fused to top section. Circular shape is a crushed silver cone with green agate |

|

|

|

|

| The Lost wax cast pendant used a piece of lapis that was polished on both sides, which the client had bought while on vacation. I thought it was better use of the stone if both sides of the pendant would produce a different design. The right side picture is in B & W and does not show the gold fused on the texture running through the centre of the piece,using the mercury gilding technique. | A pendant made from a sterling tablespoon and fork. Fused 10 K gold with a cultured pearl on top. Quartz crystal created by dropping water in a cave. Similar handmade chains on both pendants. | A friend exchanged some new sterling silver dinnerware for a piece of jewelry his wife liked. She never finished buying the silverware she started. Fused 10K gold and quartz crystals formed in a cave millenniums ago. | |

|

|

|

My young daughters favorite angel fish had died and she was heart broken. My only remedy was to make a mold of it using diluted silicone, from which I was able to make a wax model. This was used with lost wax casting for the pendant she still wears on occasion. A hand made chain finished of the piece.. |

| Fabricated silver pendent with handmade chain. Used my "anvilized" texture with depressions and balls on the surface | Centrifugal cast sterling pendant using card and various materials for burnout in the investment kiln. Balls and circular shapes soldered on after. Handmade chain | To retain the fine detail of the scales and fins, the silicone had to be made more liquid, so I tried ordinary paint thinner to dilute it, which worked perfectly. I had no catalytic casting silicone at the time so I improvised. It was in using the diluted silicone that I became aware it could be used for making waterless lithographic plates many years later | |

| Due to my time consuming freelance activities, I had stopped painting and printmaking. I continued making jewelry for my wife and friends for it filled part of my creative urge. I was asked to show at the Canadian pavilion during Expo 67 in Montreal, and had pieces accepted for the Canadian Craft Council show in Montreal during the same period. The Ontario Craft Council showed one of my silver rings at Sheridan College in 1969 and it was purchased for the colleges collection. In 1977 I was asked to submit pieces for the Canadian Craft Council annual show in Kitchener Ontario, where I got the major award given out by De Beers Consolidated. Pieces are at the Father of Confederation Museum and Sheridan College Crafts collection as well as the National Gallery from the show that finished touring Europe. |

| Bracelets |

|

|

| This bracelet was made by sand casting before I got into centrifugal casting. I made the model from 1/4 acrylic by carving the form with a flexible shaft. Sand casting is an old technique and can produce wonderful results to this day. I cast the two section as flat items, which is demanded by the process. Then I curved the pieces and constructed a hinge and a tension clasp to hold the bracelet closed. The stones are dark green Canadian jade and there is a small round stone made from lapis lazuli. Stones are held in with epoxy. A B&W photograph from the 60’s. |

|

Bracelets were a popular item and I built quite a number on commission. The one on the arm is lost wax casting in two sections and assembled with hinges and clasps that I built hidden on the inside. Flexible plastic was added to the stiffer plastic cut from a section of a detergent bottle covered with wax, then put into an investment flask for burnout and casting. Cultured pearls were added on pegs I soldered unto the surface. |

|

|

|

| The bracelet is formed by beating a rod of silver into shape and at the same time hardening it into a spring, which will hold the jewels by tension. Lapis lazuli, jade and rutilated quartz on top of a red piece of terrazzo tile that brings out the lines. The extra piece at the middle is made from quartz formed in ancient caves by dripping water. |

|

This is an original design for interchangeable bracelet in which the main color element can be changed to match clothing being worn. The simplest is at the left and are made from a sheet of silver hardened into a spring by beating and forming. The jewel elements are constructed by soldering etc. |

|

Sterling silver and welded iron were used to construct this bracelet. Jade is the stone imbedded within the sterling. The iron texture was formed using a very small oxy/acetylene torch with the color being part of the heating process. |

|

|

|

|

| Sterling silver and copper are used for this bracelet. The copper is darkened and the top edge polished | Sterling silver using “anvilized” surface texture on domed sections. Cultured pearls and silver balls added to the surfa5ce. | Sterling silver articulated bracelet built in the 60’s. I used my “anvilized” texture for the surface. |

Because I was prevented by taxation from following my desire to build jewelry for sale on a commercial basis, I kept it up more as a hobby for a number of years. Eventually my eyesight and arthritis became an impediment to continued goldsmithing – besides by 1982, I had become immersed back in printmaking as an expressive media. I now seldom attempt to produce pieces for my wife and family members. To many pieces I had not photographed before they were sold, so I have no record of just about as many pieces as on this site. At that time it was a way to make a living and it took precious time to carefully photograph the piece when finished. |

Odd Pieces

|

| At one point I became interested in what I could do with common iron and modern fabricating methods. These two iron rings are hollow and produced by welding cut pieces of iron, then burning through places to produce interesting shapes. While it doesn’t show, the tall ring on the right has three side filed to leave white metal, the rest of the area is gun blue. The left ring is all gun blued |

|

I wanted to see if I could cast a bronze bottle using lost wax techniques. I made the inner shape from fine firm Styrofoam, then covered it with wax. I dissolved the stryofoam with acetone, then filled the cavity with casting investment and forced bronze wire through the wax into the center and protruding on the outside. After filling the flask and burning out the wax, the wire would keep the inner section the proper distance from the design during centrifugal casting. The stopper was welded by using bronze rod and puddling the molten metal with an oxy/acetylene torch. The surface was chemically colored. |

| A sterling silver pill box that I made on commission for a lady. It contains a cubic zirconium and other design elements on the top. Button clasp opens hinged top |  |

|

Over the years, I have made tiaras for my daughter and daughter-in-law, as well as other jewelry for them. Both were made from sterling silver wire that was plated in 24K gold. I made a leather covered box for each piece, as well as locks using ancient Chinese technology. Stone were cultured pearls, cubics and synthetic corundum’s. I plan to take better pictures at sometime for better views of the tiaras. |

|

|

Set of stamps used to hallmark jewelry. Sterling for flat and curved surfaces, plus 14K, 10K and my personal mark |